A small and medium-sized female CEO took on the challenge of localizing parts for the defense industry.

In the manufacturing sector, where male-dominated business practices are strong, it is attracting attention because it deals with the defense industry, where even male entrepreneurs struggle.

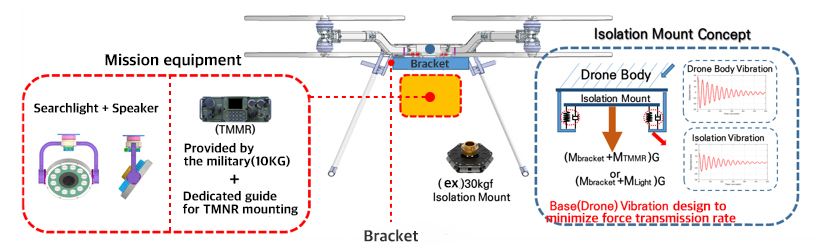

Based on the PCB design and assembly business for the defense industry, Hyeri Ahn, CEO of Taekyung Electronics, set this year’s new business goal as the localization of parts for the defense industry, which are highly dependent on overseas purchases, such as interior and exterior lights for aircraft and searchlights.

The company entered the defense industry PCB assembly business in 2015. It is operating a production line as an approved company for special processes in the defense sector of LIG Nex1 and Hanwha Systems.

This is because Taekyung Electronics secured the LED module heat dissipation board technology last year, which is essential for the development of interior and exterior lights for aircraft and searchlights. The company independently developed a metal (copper) substrate for mounting LED chips and a heat sink structure that absorbs and discharges high heat. A patent application is currently in progress.

Based on patented technology, the company has solved the problem of heat dissipation and light diffusion, and has secured technological excellence compared to other companies in performance evaluation items such as life maintenance rate, current consumption reduction, light brightness, and total luminous flux maintenance rate in the field of LED lighting. In addition, PCB assembly for the defense industry During production, we have already experienced test methods with demanding environmental requirements such as operating temperature, storage temperature, freezing, dust, impact, humidity, and altitude, so we are confident that we will meet the test standards.

Taekyung Electronics submitted a proposal to the ‘localization of interior and exterior lighting systems for aircraft’, a new product development task with purchase conditions announced by the Defense Agency for Technology and Quality, at the end of last month, and is waiting for the evaluation results. The goal of this task is to develop interior and exterior lights for military aircraft, such as location lights, anti-collision lights, control room lights, utility lights, and formation lights, within three years, and to replace purchases from foreign companies such as Goodrich and LSI.

CEO Ahn Hye-ri said, “Currently, the parts toll processing industry has a high sales ratio, but we will localize defense industry parts such as high-power lighting, anti-collision lights, and searchlights to raise the sales ratio of our products to more than 90% by 2020.”

Source : Reporter Sumin Ahn | etnews